Georgia Services

Cellular Concrete

Specialized cellular concrete applications for stronger and lighter results. On-site services include thorough quality control to meet job specifications, budget limitations, and expectations.

Georgia Services

Specialized cellular concrete applications for stronger and lighter results. On-site services include thorough quality control to meet job specifications, budget limitations, and expectations.

8960 Highway 5 Building A

Douglasville, GA 30134

Phone: (770) 439-8336

Hours: 8:00 AM - 5:00 PM EST

As Georgia’s application experts, we specialize in innovative flooring solutions that include elevated concrete, cellular concrete, underlayment, insulation, and sound mat installation. Streamline your building project by entrusting your flooring and insulation needs to the professionals at Structis.

Structis specializes in cellular concrete applications including load-reducing backfills, soil stabilization, annular space grouting, retaining wall backfill, lightweight fills and much more.

Lightweight cellular concrete is concrete made with Portland cement, water, and preformed foam air bubbles to form a lightweight fill material. Lightweight cellular concrete has many uses and benefits. Cellular concrete is often chosen for its thermal and insulative properties, and ease of placing due to its lightweight design, pumpability, and flowability. LCC is also as a cost-effective alternative to traditional fill material in certain applications.

The safety and health of our employees and clients are of the utmost importance to Structis. Our company complies with all applicable OSHA workplace safety and health requirements while maintaining occupational safety and health standards that comply with the best practices in the industry.

Gave us the best quote. Very impressed by their attentiveness and professionalism. They did a great job putting spray foam in our challenging, unique renovation project. Wouldn’t hesitate for a second to hire them again and will be doing so in the future.

Jesse arrived on time and listened to what I had to stay and was patient. Jesse was able to provide me with bids for multiple properties that were reasonable and honest. In fact, I had casually mentioned additional work that was needing to be done upon following the waterproofing, IE landscaping, concrete, etc. He incorporated those services into his bid at a very affordable rate. Needless to say, he was awarded both jobs. Structis has delivered as promised, in a timely fashion. The craftmanship, communication, job site etiquette and professionalism make Structis stand out above the rest. I’m hoping this is the beginning of a long-standing business relationship.

Scope:

Prepped seams with PW sealant

Installed Liquid Applied LM85

Added a 60-millimeter layer of Polyguard 650 membrane over the LM85

Topped it off with a drain mat and 2″ average 3000 PSI exterior pump mix, and sloped to drains with a broom finish

Contractor: Shell Mcelroy

Architect: Cooper Carey

Scope: We offered a perfect solution to a problem of a 9th floor area that was 2 1/4″ out of level on approximately 4000 s/f. The Contractor needed the floor to be leveled but the structural engineer had a weight tolerance of 12# per s/f. We were able to offer a solution by using Maxxon® Low Density Fill for all the deep fill areas and then topped and leveled the floor with Maxxon® Level-Crete.

Contractor: Summit Contracting

Scope: 300 Unit apartment complex – R-19 fiberglass batting in the walls – R-19 fiberglass batting in the floors for sound attenuation

Scope: Maxxon® Acousti-Mat® 3/4 Premium

Contractor: Fortune Johnson

Scope: 1” Maxxon® Gyp-Crete® 2000 Multifamily over Acousti-Mat® 3/8 Premium

Contractor: Fortune Johnson

Scope: Waterproofed balconies: installed T-bar flashing and poured exterior mix concrete.

Scope: 159,700 sq. ft. Maxxon® Acousti-Mat® 3/4 Premium Installed Throughout Floors 3-7 and Penthouse Level

Scope: 6,353 total square feet Aquafin® Vaportight Coat® SG3 capped with 1″ average Maxxon® Gyp-Crete® High Performance

Scope: 27,000 sq. ft. of Commercial Topping poured at an average depth of 1-1/4″

Contractor: Character Build

Scope: 21,330 sq. ft. 2” Maxxon® Gyp-Crete® High Performance over dual sound mat system of Maxxon® Acousti-Mat 3/4, Maxxon® SBR, and Maxxon® Reinforcement Renovation of old building to a new hotel

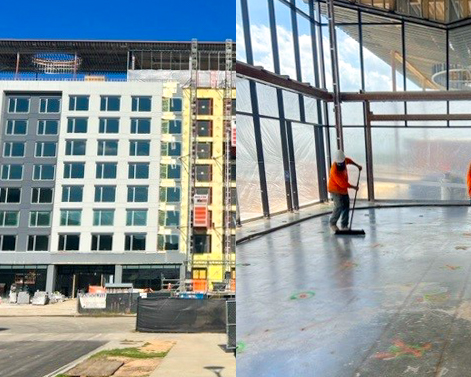

Contractor: CBG Builders

Scope: Pouring 1” Maxxon® Gyp-Crete® 2000 Multifamily over Maxxon® 1/4” Acousti-Mat® over prescient metal decking on 14 story high rise apartment building

Contractor: Whaley Construction

Scope: 95,000 sq. ft. 11/2” Maxxon® Gyp-Crete® 2000 Multifamily over Maxxon® Acousti-Mat® 3/4 with Maxxon® Reinforcement

Contractor: Brassfield Gorrie

Scope: 7,700 s/f Maxxon® Level-Crete poured at 5/8”-1 1/2” over concrete slab at 4000 psi

Cellular concrete is a type of concrete that is made using Portland Cement, water, and a preformed foam. The foam is combined with the cement slurry using a static mixer. The resulting concrete is lightweight, very flowable, and stable with virtually no bleed water.

In order to create the proper cellular concrete mixture, foam liquid concentrate is run through a foam generator, which combines air, water, and the concentrate to create a preformed foam (air) bubble. These small, highly-stable air bubbles are mixed with a cement slurry through inline-injection, and pumped via a hose to the fill location.

The main value proposition of cellular concrete is that it can be used in a variety of applications where a strong, lightweight fill material is required such as slope stability fills, annular space fills, and abandonment applications. It is also used for bridge abutment and retaining wall backfill.

Cellular concrete has a much lower density than traditional granular fills. Standard granular fill has a density of approximately 120 pounds per cubic foot (PCF) whereas the most common cellular concrete applications are in the 30 PCF range. Cellular concrete should be viewed as a soil replacement when considering strength. Even at its lightest density, cellular concrete is stronger and more durable than the best compacted soils. Common applications of cellular concrete yield a bearing capacity of over 14,000 pounds per square foot (PSF).

There are several benefits and advantages of using cellular concrete as a solution on your next project. Cellular concrete has these properties and benefits:

The first step to exceptional services is getting in touch.